The Advantages of iTPMS vs dTPMS

A Modern Approach to Tire Pressure Monitoring

In today's automotive industry, technology plays a crucial role in enhancing safety, performance, and efficiency. One innovation at the forefront of this transformation is the Indirect Tire Pressure Monitoring System (iTPMS). Unlike traditional Direct Tire Pressure Monitoring Systems (dTPMS), iTPMS offers several distinct advantages that make it an attractive choice for both manufacturers and drivers. Let's explore what makes iTPMS a superior solution in many scenarios.

What is iTPMS?

iTPMS is a technology designed to monitor tire pressure without using physical sensors inside each tire. Instead, it leverages data from existing vehicle systems, such as wheel speed sensors, to detect changes in tire pressure. By analyzing the rotational behavior of the wheels and comparing them against each other, iTPMS can infer if a tire is underinflated.

1. Cost-Effective Implementation

One of the most significant advantages of iTPMS is its cost-effectiveness. Since it uses existing sensors and vehicle systems, there is no need for additional hardware inside the tires. This not only reduces manufacturing costs but also eliminates the need for expensive sensor replacements or maintenance.

For vehicle manufacturers, integrating iTPMS means fewer components to produce and install. For consumers, it translates to fewer costs over the vehicle's lifetime—no sensor battery replacements or maintenance related to physical components inside the tire.

2. Simplified Maintenance

Traditional dTPMS relies on individual sensors mounted inside each tire, which can require recalibration or replacement after a tire change. iTPMS, however, is self-calibrating and doesn’t depend on specific tire hardware. When you rotate or replace your tires, iTPMS automatically adapts, reducing the need for complex recalibration processes.

This advantage is particularly valuable in fleet management, where minimizing vehicle downtime is crucial. Simplifying maintenance procedures can lead to significant cost savings and operational efficiency.

3. Improved Reliability and Durability

Sensors inside tires are subject to extreme conditions, including heat, pressure, and vibrations, which can lead to wear and failure. iTPMS, being sensor-free, avoids these challenges. By relying on data from robust vehicle systems like ABS (Anti-lock Braking System) and ESC (Electronic Stability Control), iTPMS provides reliable, long-term performance without the risk of sensor damage.

4. Environmental Benefits

Reducing the number of components inside tires has positive environmental implications. Fewer physical sensors mean less electronic waste. Additionally, well-maintained tire pressure improves fuel efficiency, reducing carbon emissions. Studies show that underinflated tires can decrease fuel efficiency by up to 3%, and iTPMS helps ensure optimal pressure to mitigate this impact.

5. Seamless Integration with Modern Vehicles

iTPMS is inherently compatible with the growing trend of software-defined vehicles. As cars become increasingly dependent on software for functionality and diagnostics, iTPMS fits naturally into this ecosystem. With over-the-air (OTA) updates, manufacturers can improve or refine iTPMS algorithms, enhancing performance without requiring any physical changes.

6. Compliance with Regulations

In many regions, tire pressure monitoring is mandated by law to improve road safety. iTPMS meets these regulatory requirements efficiently. With ongoing advancements in software and data analytics, iTPMS can even exceed some of the performance benchmarks set by traditional dTPMS systems.

7. Enhanced Driver Experience

Modern drivers expect intuitive, low-maintenance solutions. iTPMS provides a smooth, hassle-free experience. With fewer dashboard warnings and simplified maintenance, drivers can focus more on the road and less on managing tire sensors.

Moreover, advanced iTPMS systems can offer predictive diagnostics, warning drivers about potential issues before they become critical. This proactive approach enhances safety and convenience.

Looking Ahead: The Future of iTPMS

As vehicles continue to evolve, so will tire pressure monitoring systems. iTPMS is poised to play a key role in future mobility, especially with the rise of electric vehicles (EVs) and autonomous driving. These technologies demand reliable, low-maintenance solutions, and iTPMS fits perfectly into this vision.

NIRA Dynamics are leading the way by continuously innovating and enhancing iTPMS capabilities. By integrating AI and advanced data analytics, the future of tire pressure monitoring promises even greater accuracy, reliability, and functionality.

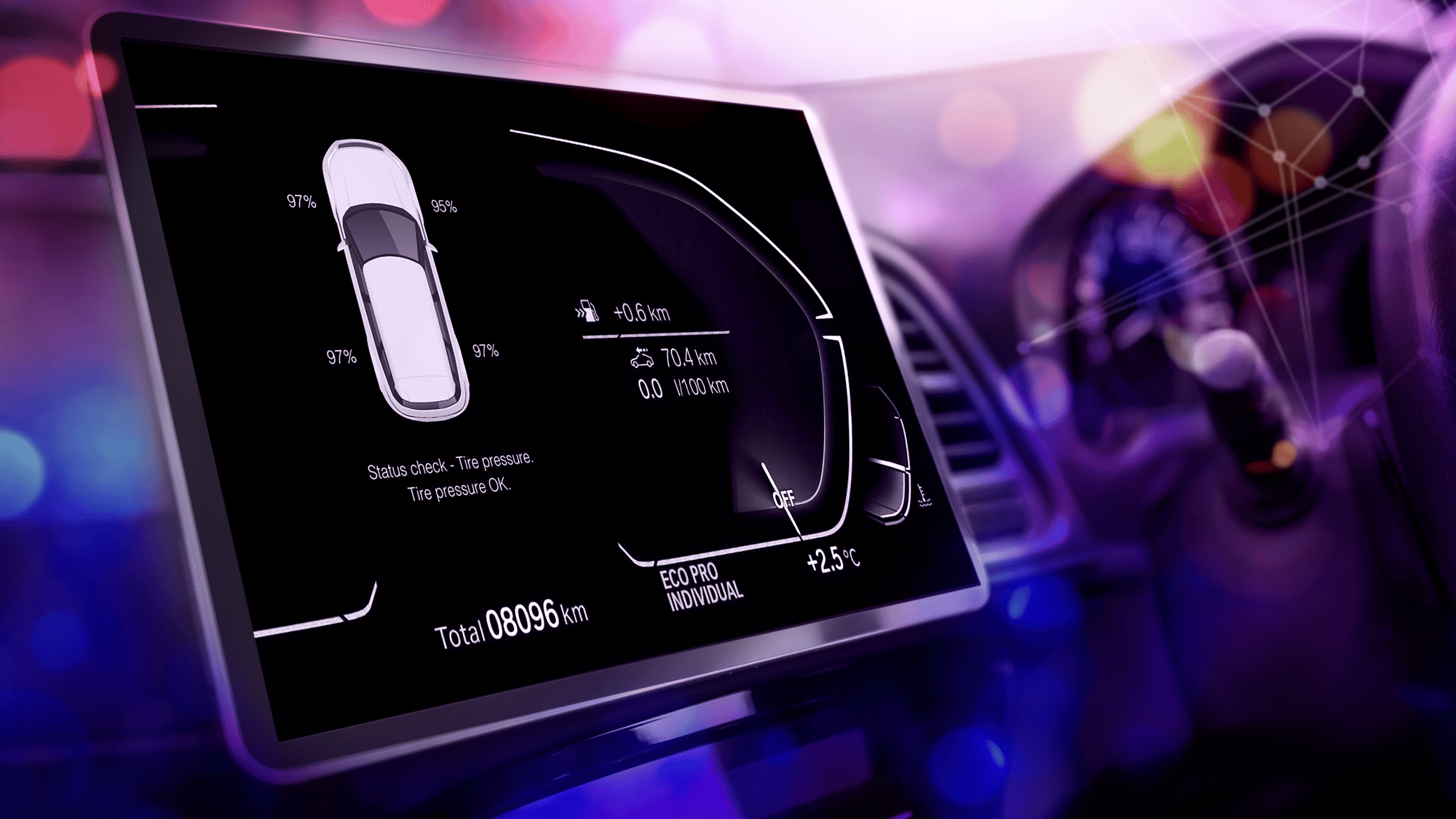

Tire Pressure Indicator UX: The Future of User Experience

One of the most exciting advancements in iTPMS is the development of Tire Pressure Indicator UX. This next-generation user experience focuses on delivering clear, actionable information to drivers through intuitive interfaces. Instead of generic warnings, Tire Pressure Indicator UX provides detailed insights into tire conditions, making it easier for drivers to understand and address issues proactively.

With user-friendly visuals and real-time feedback, drivers can quickly identify which tire needs attention and why. This not only enhances safety but also improves overall vehicle maintenance. As the automotive industry moves towards more connected and software-driven experiences, advanced UX solutions like this will become a standard, ensuring that drivers are well-informed and empowered to maintain optimal tire performance.

| Feature | iTPMS | dTPMS |

| Hardware Requirements | Uses existing wheel speed sensors | Requires dedicated pressure sensors in each tire |

| Maintenance Cost | Minimal - software-based system | Higher - sensors need replacement (3-7 years) |

| Installation | Integrated with existing systems | Requires physical sensor installation |

| Calibration | Self-calibrating | May require manual calibration after tire service |

| Accuracy | Indirect measurement, algorithmic detection | Direct pressure measurement |

| Battery Requirements | No additional batteries | Requires sensor batteries |

| Environmental Impact | Lower - no additional hardware waste | Higher - sensor replacement creates e-waste |

| Tire Service | No special considerations needed | Careful handling of sensors required |

| Integration | Seamless with modern vehicle systems | Requires dedicated receiver system |

| Durability | High - no physical wear on components | Medium - sensors subject to tire environment |

| Additional Features | Can detect multiple tire conditions | Primarily pressure monitoring |

Learn more about Tire Pressure Indicator UX