Corrective & Preventive Maintenance using NIRA Roughness data

Road maintenance is a critical aspect of infrastructure management. As road agencies strive to preserve and maintain pavements, they employ various strategies to ensure longevity and safety.

Together with predictive maintenance (see citation), Corrective and Preventive Maintenance (CPM) are fundamental considerations when seeking to maximize pavement durability. Corrective measures address existing issues, such as potholes, cracks, and surface distress. Preventive actions, on the other hand, proactively mitigates potential damage from arising. For roads maintenance strategies to be successful, road monitoring plays a pivotal role.

Many road agencies and municipalities rely on visual inspections to assess pavement condition. Experienced personnel conduct these inspections, identifying signs of wear, distress, and deterioration. However, this approach has limitations; it depends on individual expertise, is time consuming and costly, is limited to visible defects, only provides a ‘snapshot’ of road condition, and can entail safety concerns for the public and inspectors.

In recent years, technological advancements have revolutionized road monitoring. NIRA Dynamics are at the forefront of this transformation, and leverage crowd-sourced data from connected vehicles. Their innovative solution, NIRA Roughness Change Alerts, continuously tracks road surface conditions and roughness evolution to determine when a substantial change in pavement condition has occurred. These insights have empowered decision-makers to quantify distress development at any given moment, enabling effective prioritization of corrective and preventive actions.

In summary, a holistic approach that combines traditional expertise with innovative technologies is essential for maintaining road pavements. By integrating CPM strategies and leveraging data-driven insights, road agencies can ensure safer, smoother journeys for all travelers.

Roughness change alerts description

Nira's Roughness Change Alerts are a data-driven solution for assessing road roughness changes and highlighting pavement sections that might require further evaluation or maintenance. Here’s how it works: Nira ensures continuous access to real-time road data. Any vehicle within the connected fleet provides roughness values as it drives along the road. These values reflect the surface's physical condition. The average of individual measurements produced during a day is saved as daily roughness. Recognizing that vehicles follow different paths, data also reports daily roughness variance to add context to the measurements.

Using properly aggregated historical roughness data, Nira automatically determines the roughness baseline for each road section. This baseline reflects the latest stable condition. When consecutive daily roughness measurements deviate significantly from this baseline, Nira triggers alerts. These alerts prompt timely corrective and preventive actions, ensuring road administrators can address issues before they escalate.

Application and Interpretation

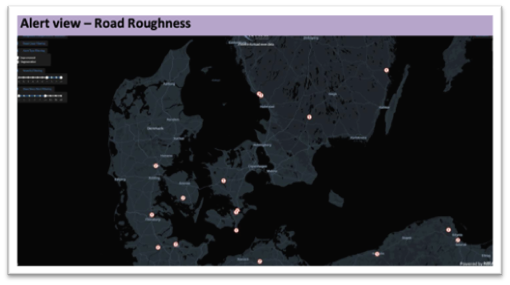

Roughness change alerts, appear in the Nira Graphical User Interface (GUI), or can be accessed via an API (Figure 1).

The GUI allows filtering of alerts based on:

- time since release and

- severity,

This enables authorities to formulate a prioritization strategy. Furthermore, data related to each alert are easily accessible, allowing a detailed understanding of the phenomenon that triggered it.

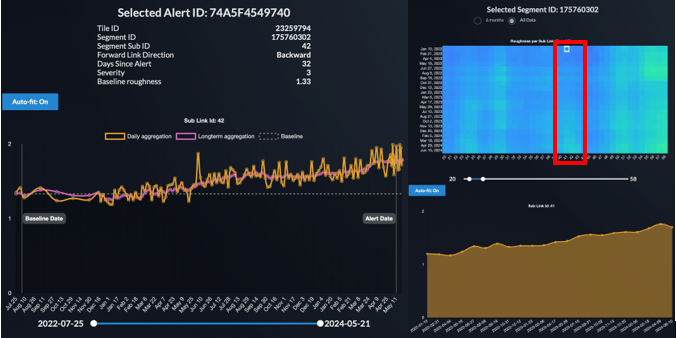

Alerts triggered by a low roughness development rate

The following example refers to an alert that was triggered due to a consistent and linear trend in roughness development, which deviated from the established baseline (dotted line) (Figure 2, left). Given the constant rate of roughness development over an extended period and the starting roughness value, severe surface distresses are unlikely to be the cause. This supports the hypothesis of potential structural damage and settlement. To establish if the problem extends to proximal sections and determine the length over which the inspection or survey should be completed, data from nearby sections can also be accessed (Figure2, right). By looking at the heatmap, with the x and y axis representing respectively consecutive sections and time, the user can establish over which length the phenomena is extending.

Figure 2: left. Alert detail accessed with GUI; right. Check over near sections

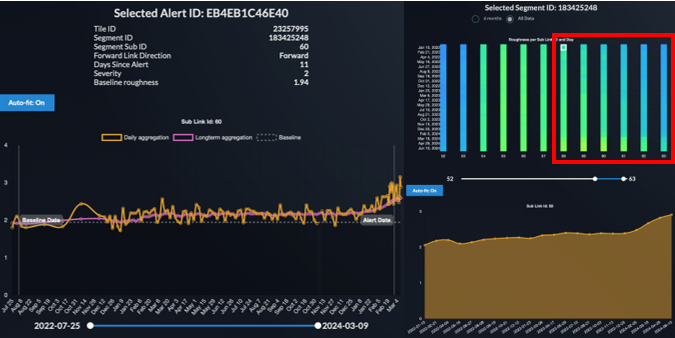

Alerts triggered by a high roughness development rate

The example given in Figure 3 represents an alert that exibiths a higher development rate. In this case, the alert was caused by surface deterioration. The development rate started increasing in January and within a relatively short time caused a significant change in IRI. This is typical for surface distresses which increase in severity within a short period of time, often triggered by adverse external conditions such as low temperature and rain.

If the alert leads to a treatment of the surface, then it is possible to monitor the performance of the repair and assess its effectivenss (Figure 4).

Applications

Nira Dynamics' Roughness Change Alert service is a cutting-edge technology that significantly enhances road monitoring capabilities. This service is crucial when planning inspections or surveys with traditional equipment, as it provides real-time data on road conditions. By identifying changes in road roughness, it enables road administrators to allocate resources more effectively, focusing on network elements that show signs of deterioration.

This technology also detects problems which are not detected by visual inspectors because they are caused by structural deformation or settlements, representing unique support in identifying underlying issues. Additionally, the Roughness Change Alert is particularly beneficial for monitoring areas prone to rapid wear and tear, such as bridge expansion joints, transversal joints, and ramps. These structures are often subject to more significant stress and faster deterioration due to their complex construction and heavy usage.

The continuous monitoring provided by this technology also allows administrators to track repairs and assess their effectiveness over time. By using this advanced technology, road administrators can proactively address potential issues before they escalate, maintaining safer and more reliable road networks in a cost-efficient manner.

In fact, Roughness change alerts allow users to define an inspection order where a given list of alerts, appropriately based on similarities in the development rate and location, are listed.